Today, Makitta has become one of the world's largest power tool manufacturers, and its products enjoy a global reputation. The brand is known for its high quality, durability and innovation, providing excellent tools for both professionals and home project enthusiasts. Makitta always adheres to the principle of "quality first, customer first" and provides users with first-class products and services.

To celebrate this collaboration, renowned Japanese tool brand Makitta hosted an online event with Facebook.

Limited 50% off.

Event only lasts until the end of April, don't miss it!

FB users only.

Free Shipping + Cash on Delivery + 5 Year Warranty

Limited Quantity, Don't Miss It

Only for FB Users!

With over 120 service centers nationwide, we offer a worry-free warranty and 24/7 customer support. If you have any questions about the product, please feel free to contact us.

Customer support contact email: contact@florency-service.com

After placing the order, the goods will be shipped within 12 hours.

Due to traffic problems in the area, delivery times may vary. Please wait!

We offer free repairs, free shipping and cash on delivery services!

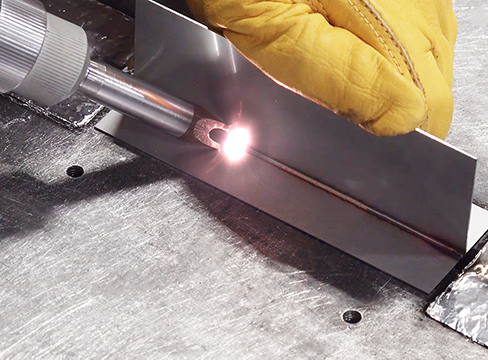

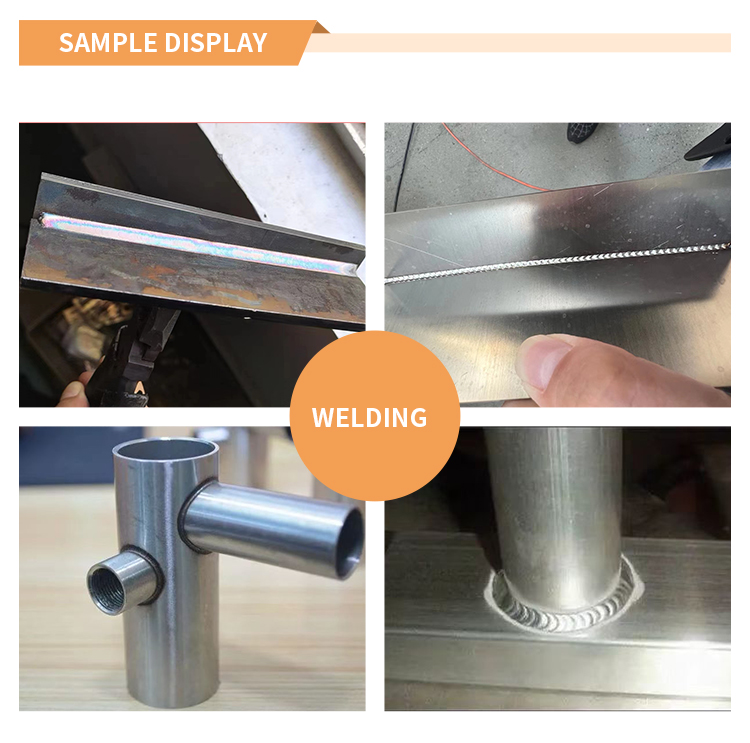

Don't have a professional welder?

nothing

Even beginners with no welding experience can create perfect welds with our laser welders.

One day of training is usually enough to achieve acceptable welding results.

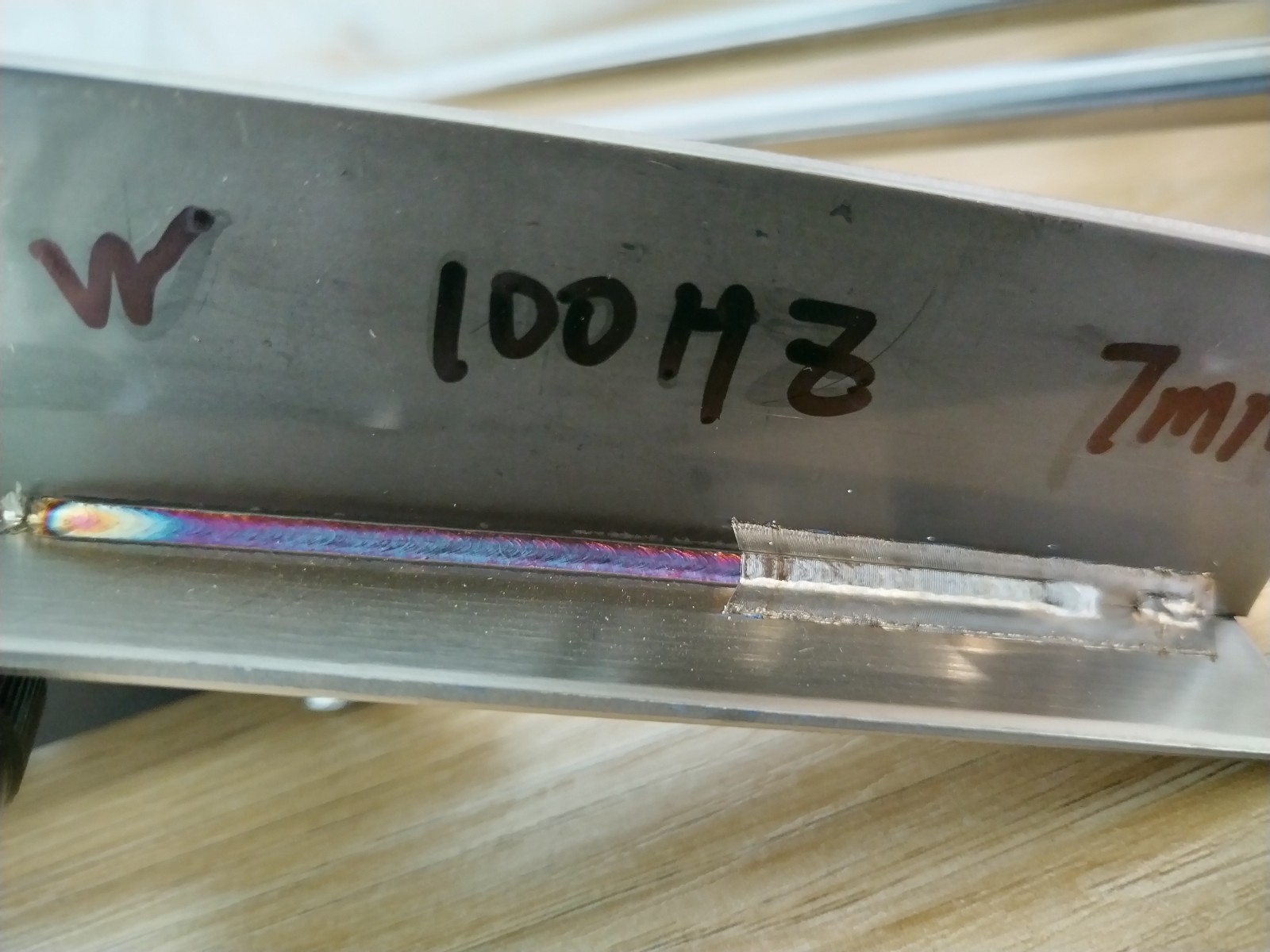

Why use laser welding?

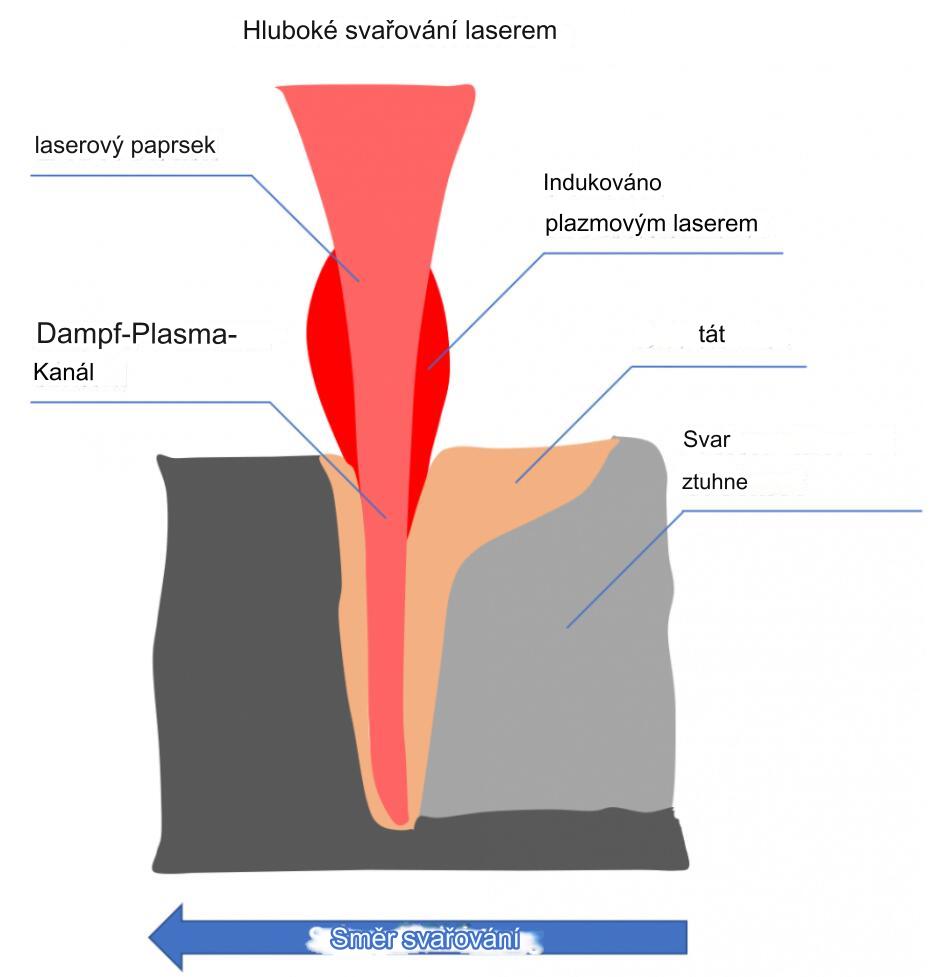

The penetration depth of 7KW is 10-30 mm.

Get good results without wire feeding

It is easy to get good results even without a certified welder.

Thanks to the very high intensity of our 9000 W laser, the joint area of the workpiece reaches vaporization temperatures, allowing deep welding.

It can perform laser welding, cutting, weld seam cleaning and pickling at the same time.

Power up to 9000 W

There is no need to buy additional equipment for these different jobs, just one innovative 4-in-1 Makitta laser welder can weld, clean and cut at the same time.

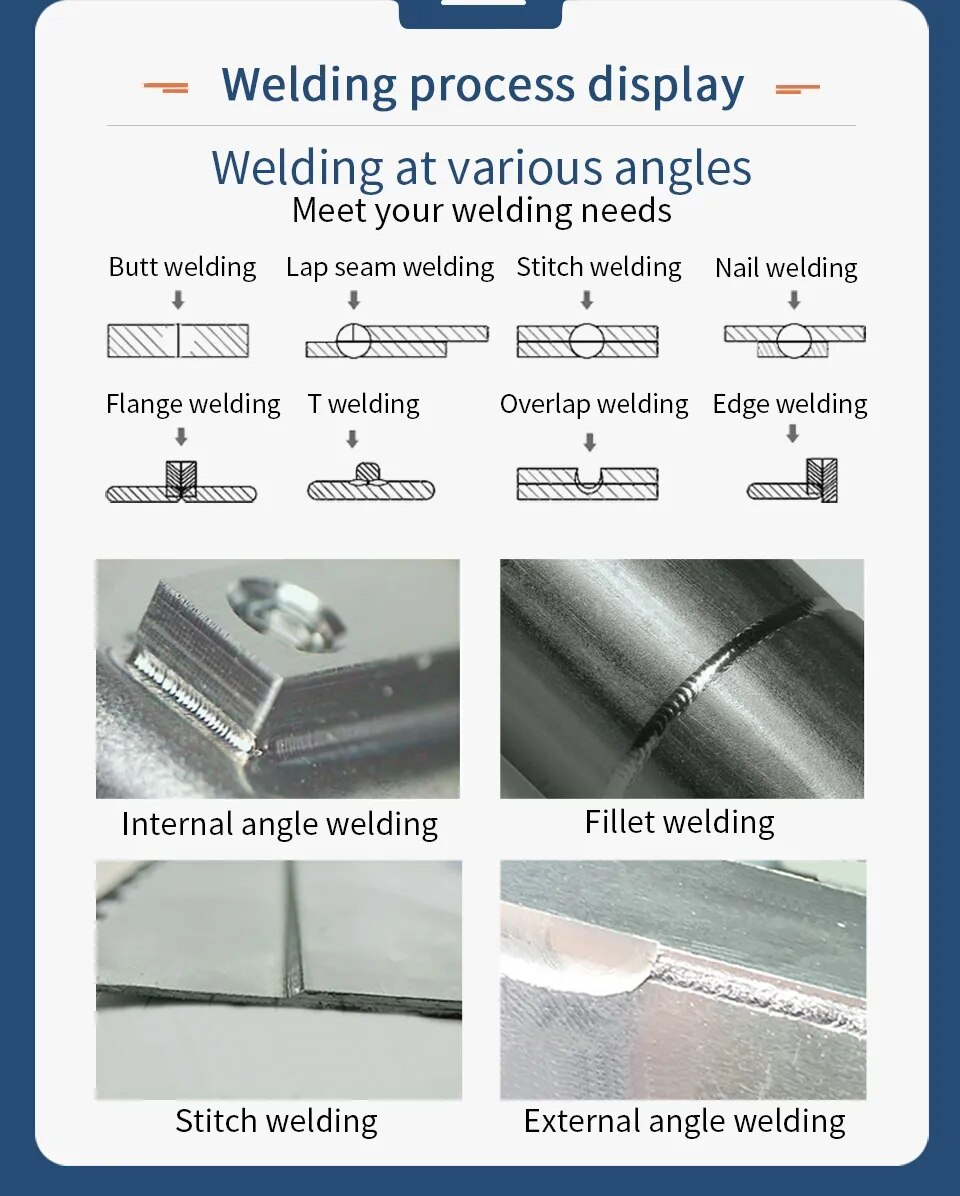

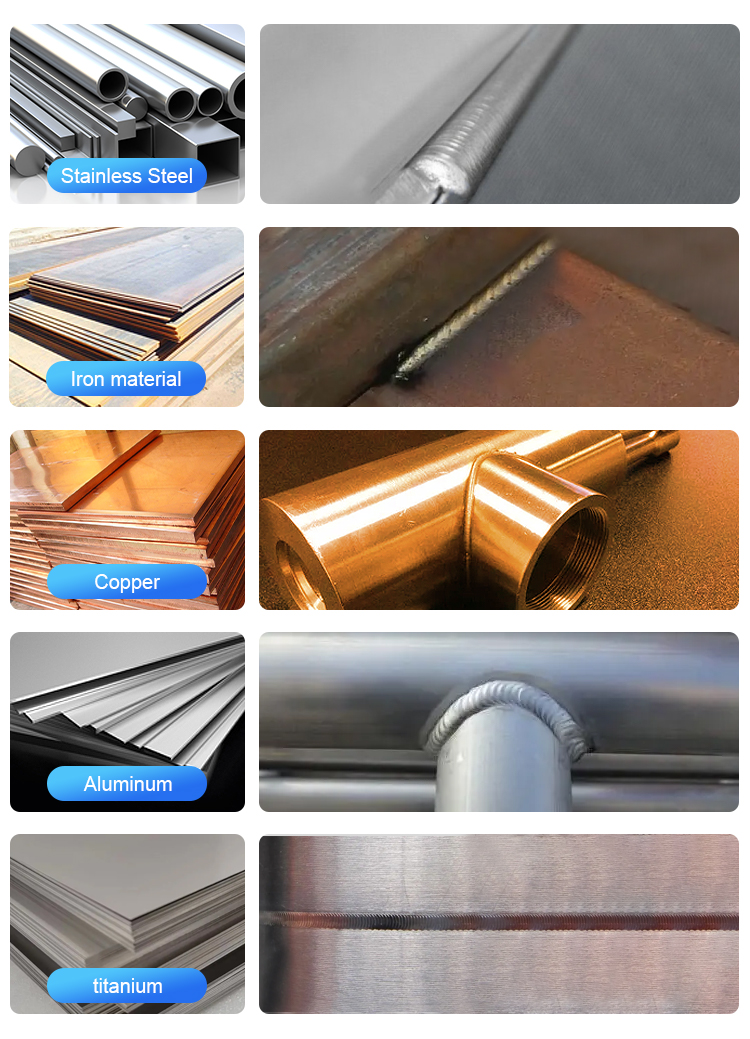

In the past, laser welding machines were widely used to weld stainless steel, carbon steel and aluminum alloys.

Now, the new application of laser welding machine will be copper welding, which can even weld different materials, such as copper and stainless steel welded together. We also achieve good welding performance on a variety of materials.

Weld cleaning before or after welding is a common application to improve weld performance and surface quality.

Remote cleaning width up to 80 mm, weld seam cleaning width up to 10 mm

Laser cleaning and rust removal technology has the advantages of high cleaning speed, good cleaning effect, no additional pollution, precise control, and no consumables.

Advantages of portable laser welding machines

1. Can be welded in the outdoor environment.

2. High welding speed, 2 to 10 times faster than traditional welding.

3. The weld is smooth and beautiful, with large depth and small taper. No grinding is required, saving time.

4. No deformation, no welding marks, and the workpiece is firmly welded.

5. Compared with contact welding, laser welding does not require electrodes, which reduces daily maintenance costs and greatly improves work efficiency.

6. Welding of thin stainless steel plates, iron plates, aluminum plates and other metal materials can perfectly replace traditional argon arc welding technology and electric welding.

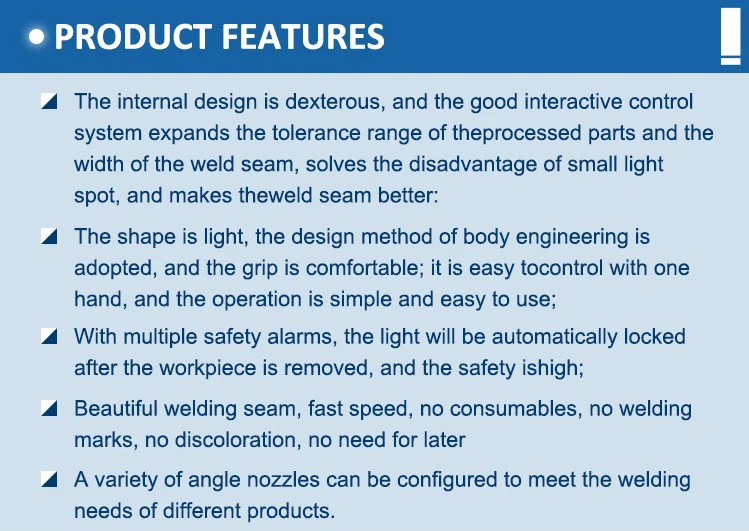

Makitta 4-in-1 Innovative Portable Laser Gun

Small size, easy to carry, suitable for daily work

Manual welding, flexible and convenient, longer welding distance

Adapt to different welding requirements, set multiple safety alarms and status indicators, and respond immediately to abnormal situations.

Lamp body design and insert protective lens design

When welding or laser cutting, especially when welding highly reflective materials such as aluminum alloy or carbon steel, more spatter will be generated.

Inserted protective lenses are easy to replace for routine operation and maintenance, providing maximum protection of the internal mirror against focusing, reflection and collimation effects.

Switching from laser welding to laser cutting is as easy as replacing a welding nozzle with a cutting nozzle.

If you need to switch from laser welding/cutting to laser cleaning, you can simply replace the focus lens insertion tool and cleaning nozzle for direct metal removal.

Cutting stainless steel is easy, you can cut straight or curved lines or any shape you want, it can also cut steel with a thickness of 0-30 mm.

Laser welding nozzles include ordinary welding nozzles and feed welding nozzles.

The advantage of the nozzles we use is that they spray less than traditional nozzles.

Depending on the material, there are brass and copper nozzles to choose from, of which copper nozzles have better heat dissipation performance than brass nozzles.

It also has the most reliable safety certification in the world.

Stable high power of 9000W, welding speed 30m/min,

Welding stainless steel, steel, aluminum alloy etc...

Portable laser welding technology uses a laser beam as an energy source to impact the welding plate and form a weld.

It not only solves the problems of traditional welding, but also increases the waterproofness when working underwater and on rainy days (completely avoiding the problem of not being able to work on rainy days, greatly improving work efficiency).